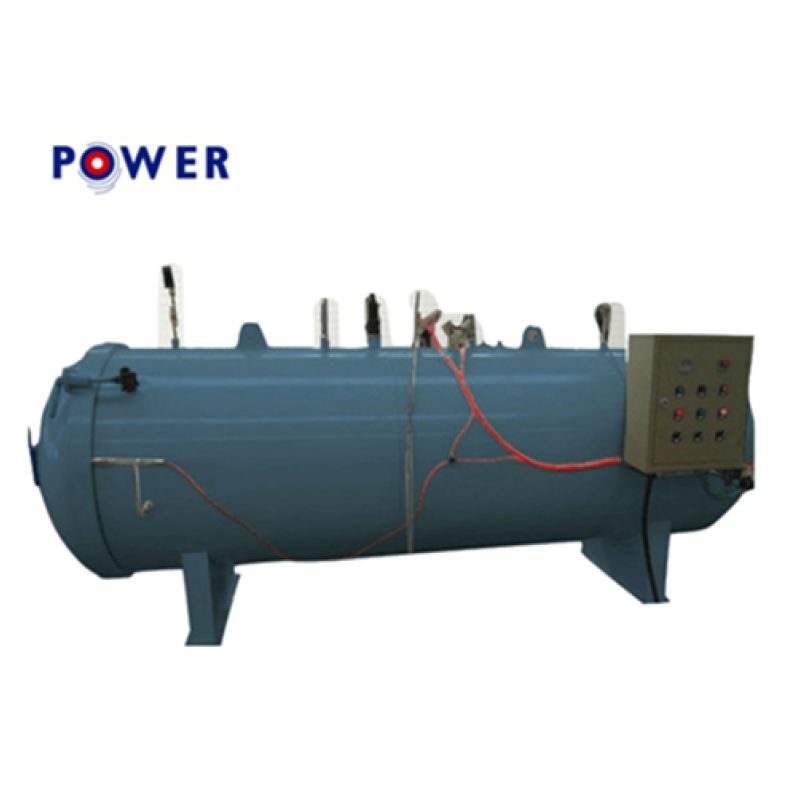

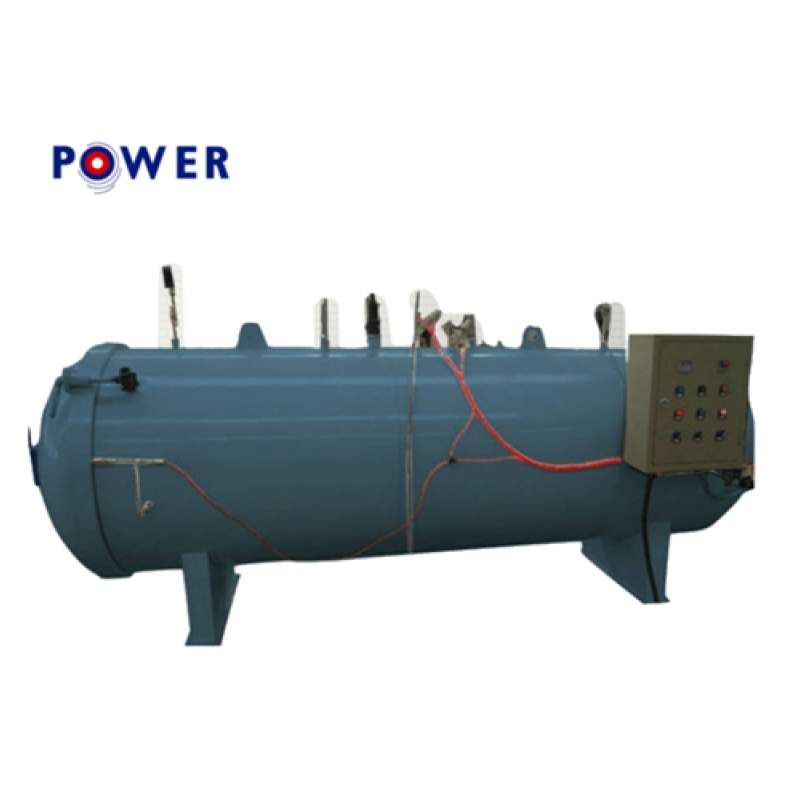

Roller boiler standerand configurations: -diameter 1500 * duration 4000 mm -fabric: q345r -thickness of the vulcanizer: 8mm -thickness of the give up enclosure: 8mm -designed strain: 0.85mpa -designed temperature: 180c -automated heating vulcanizer, temperature, stress, and heating time, are controled via laptop.

Contact Now

Roller boiler standerand configurations: -diameter 1500 * duration 4000 mm -fabric: q345r -thickness of the vulcanizer: 8mm -thickness of the give up enclosure: 8mm -designed strain: 0.85mpa -designed temperature: 180c -automated heating vulcanizer, temperature, stress, and heating time, are controled via laptop.

Contact Now

Roller Boiler Standerand Configurations: -Diameter 1500 * Length 4000 mm -Material: Q345R -Thickness of the vulcanizer: 8mm -Thickness of the end enclosure: 8mm -Designed pressure: 0.85mpa -Designed temperature: 180C -Automatic heating vulcanizer, temperature, pressure, and heating time, are controled by computer.

Contact Now

Roller Boiler Standerand Configurations: -Diameter 1500 * Length 4000 mm -Material: Q345R -Thickness of the vulcanizer: 8mm -Thickness of the end enclosure: 8mm -Designed pressure: 0.85mpa -Designed temperature: 180C -Automatic heating vulcanizer, temperature, pressure, and heating time, are controled by computer.

Contact Now

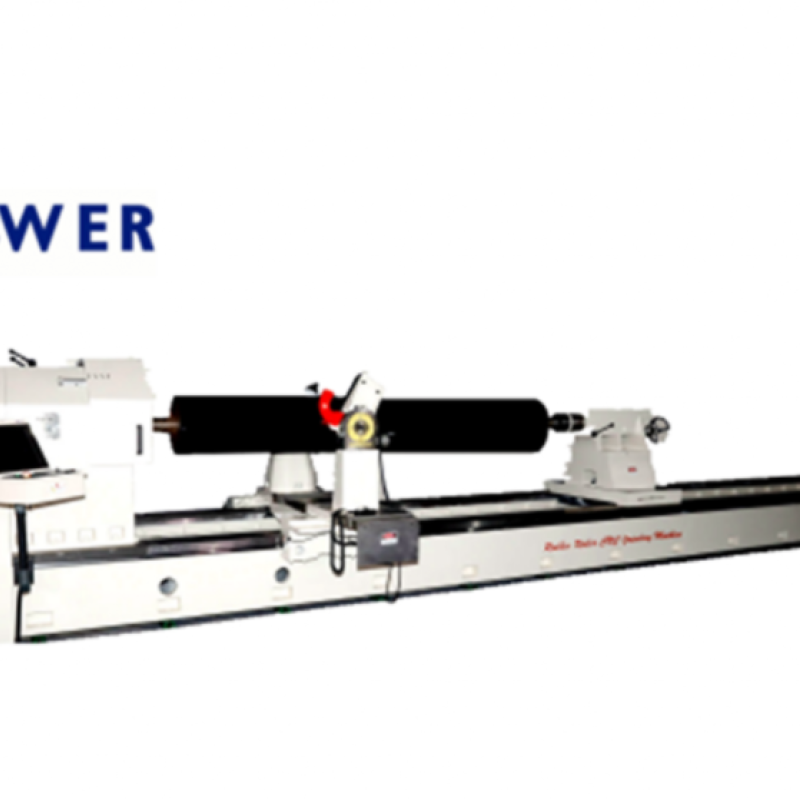

Because of the all-round of the device characteristic, manufacturing unit customized rubber curler groover should make nearly all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

Because of the all-round of the device characteristic, manufacturing unit customized rubber curler groover should make nearly all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

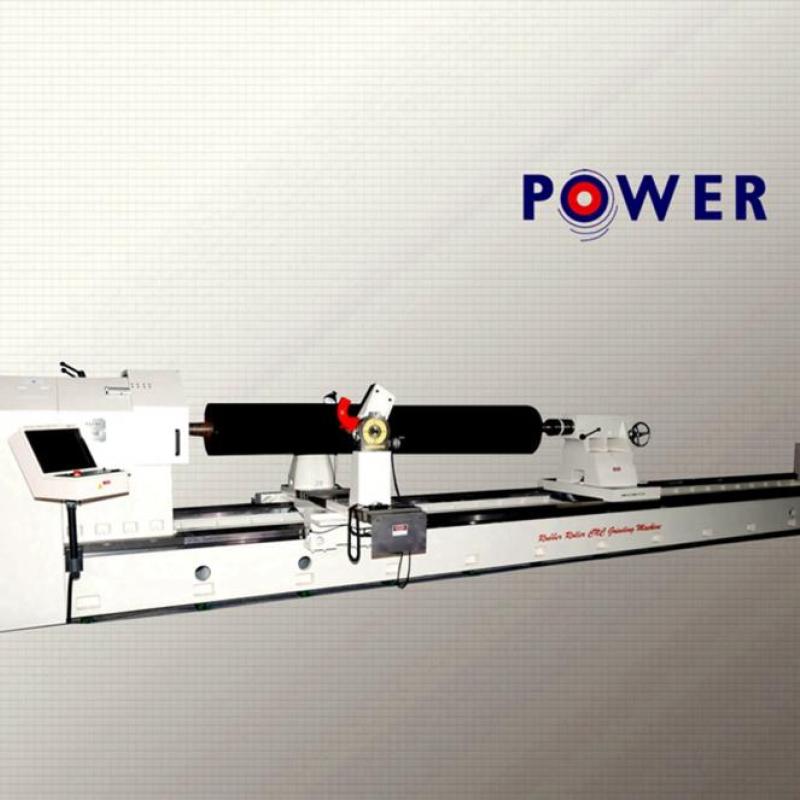

1. Factory custom designed rubber curler groover has our personal advanced user-pleasant CNC running gadget.2. The modern CNC gadget can without difficulty perform extra than 35 shapes at the rubber curler surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, immediately groovings, etc. 3. Remote trouble fixing characteristic availabe.4. Having all of the capabilities of our PSM collection preferred grinding machineDue to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

1. factory customized rubber roller groover has our personal developed user-pleasant cnc operating system.2. the contemporary cnc gadget can without problems perform more than 35 shapes on the rubber roller floor, which incorporates: crowning, concave,and wave grindings; herringbone, diamond, directly groovings, and many others. 3. far off problem fixing feature availabe.4.

Contact Now

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contact Now

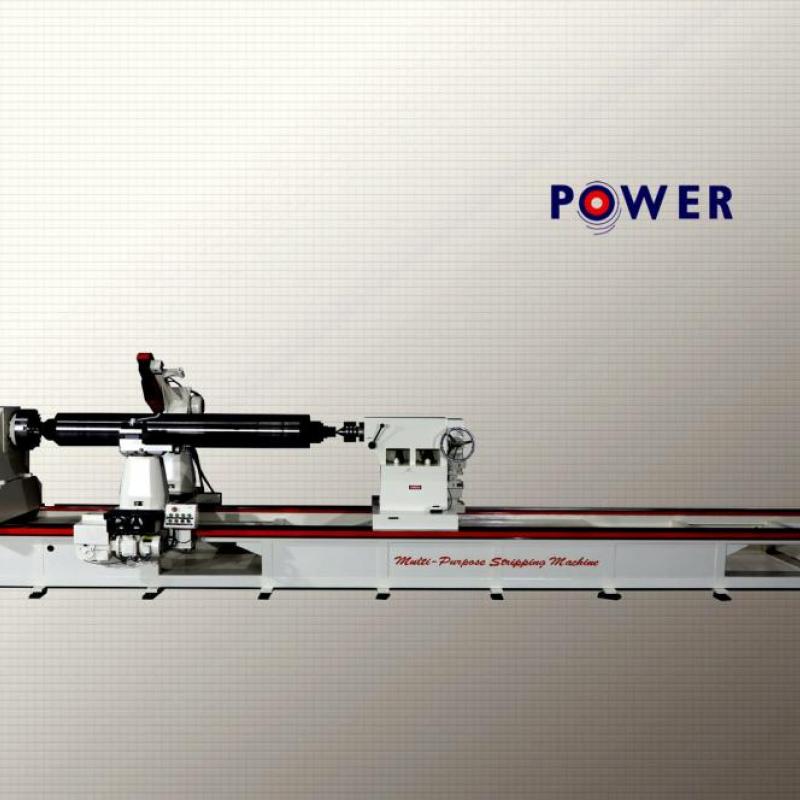

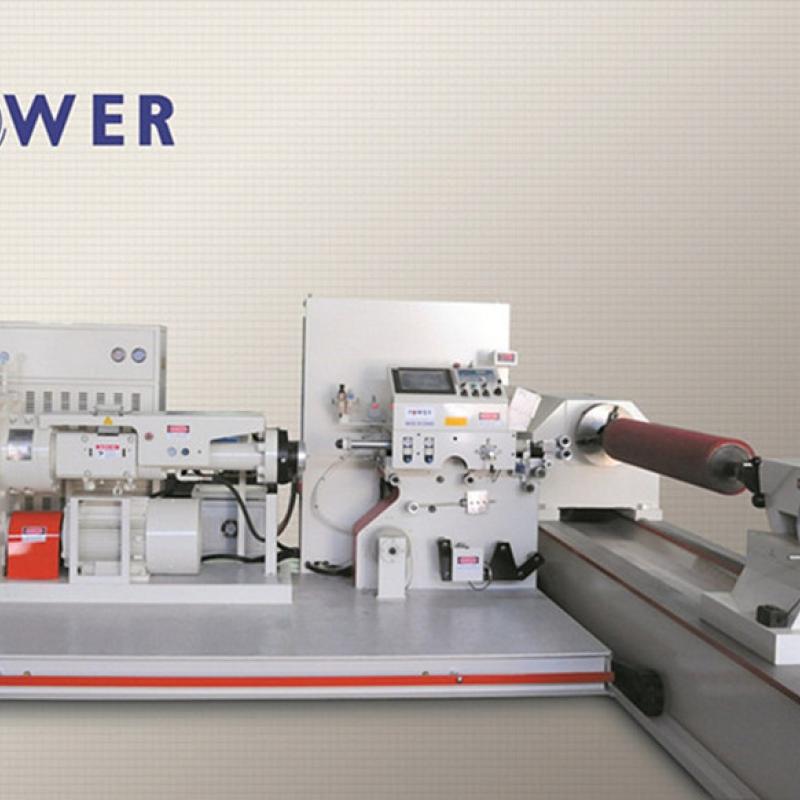

Product description1. The PCM-1250 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system. MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Because of the all-spherical of the tool function, production unit customized rubber curler groover should make nearly all of the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, at once groove, horizontal groove and exceptional formations in the appended drawing.1. factory customized rubber roller groover has our personal developed user-pleasant cnc operating system.2.

Contact Now

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

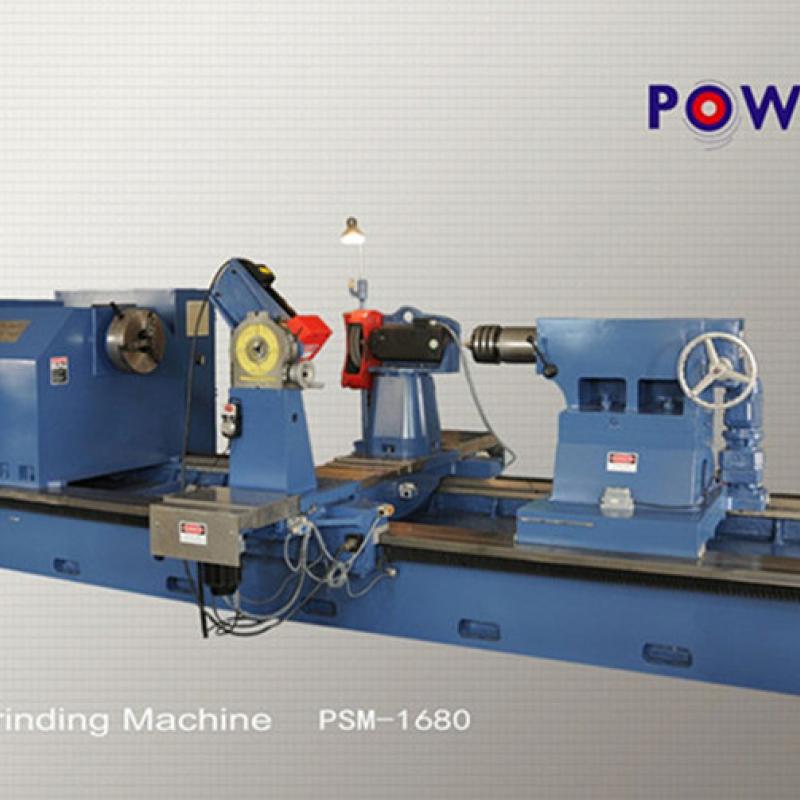

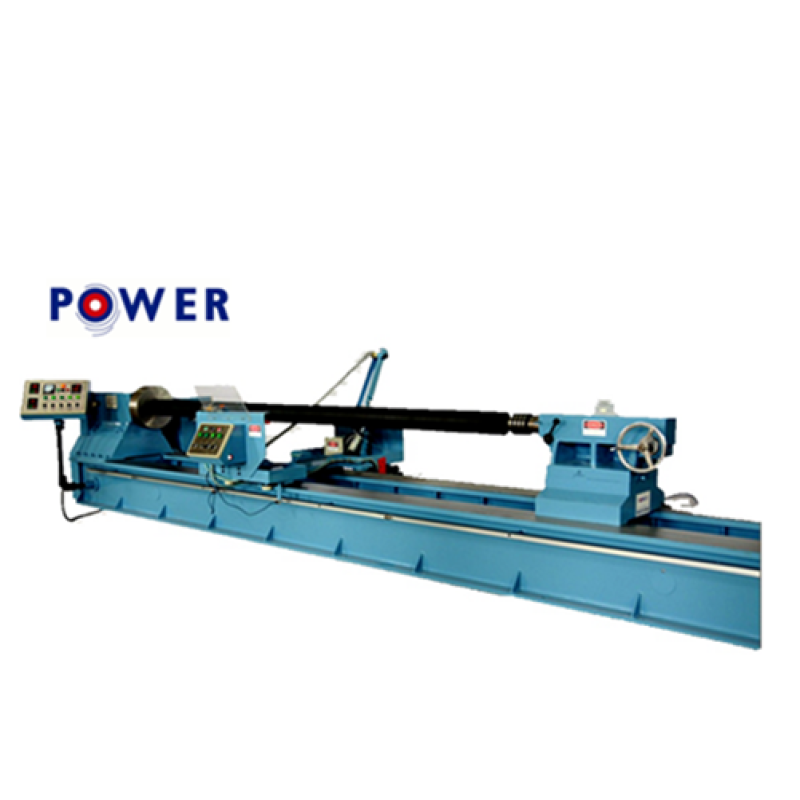

Psm collection rubber roller grinding device is in particular designed and synthetic to update the beyond roller processing approach thru using manner of metallic production device. installation grinding head at the engine lathe is the past technique to manufacture roller, which the super of curler is hard to gain the requirement of the winning giant. the primary cause lies inside the shape of lathe. ultimately, it isn't the grinding device; the moving regions of the big and medium carriage table are massive than that of grinding tool.

Contact Now

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contact Now

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

Factory Price Rubber Roller PolisherMore than 8 merchandise have been provided countrywide or shandong provincial stage product prizes and three scientific-studies achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5. On-site training service provided.6.

Contact Now

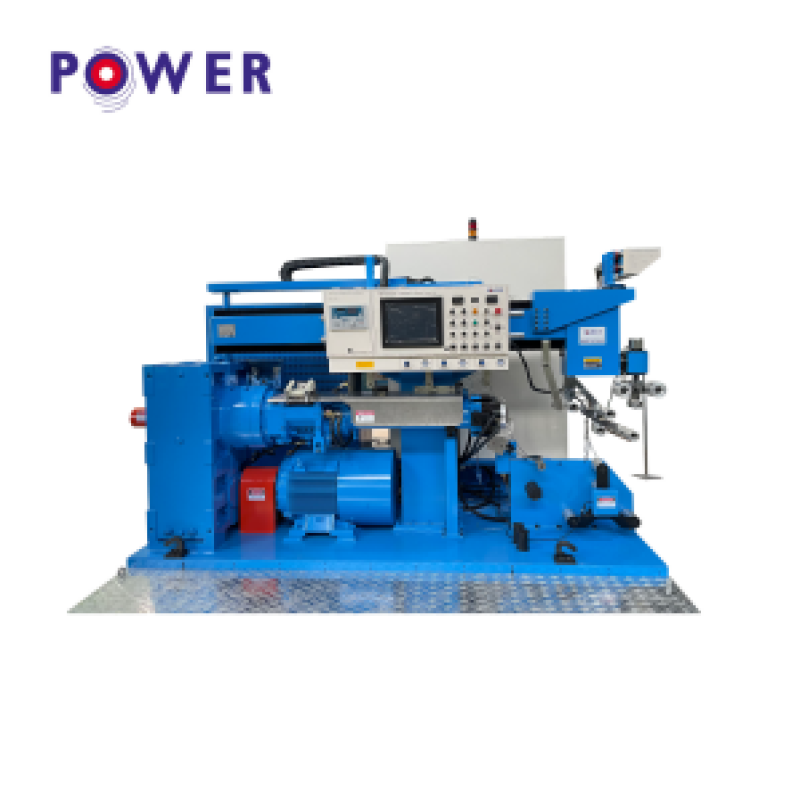

PTM-1510 Printing Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contact Now

Psf rubber curler surface measuring instrument is specifically designed and manufactured for rubber roller production firms. it's a kind of unique testing device include the most advanced laser probe. it can make dimension for any apparent tolerance and roughness on floor of rubber rollers.

Contact Now

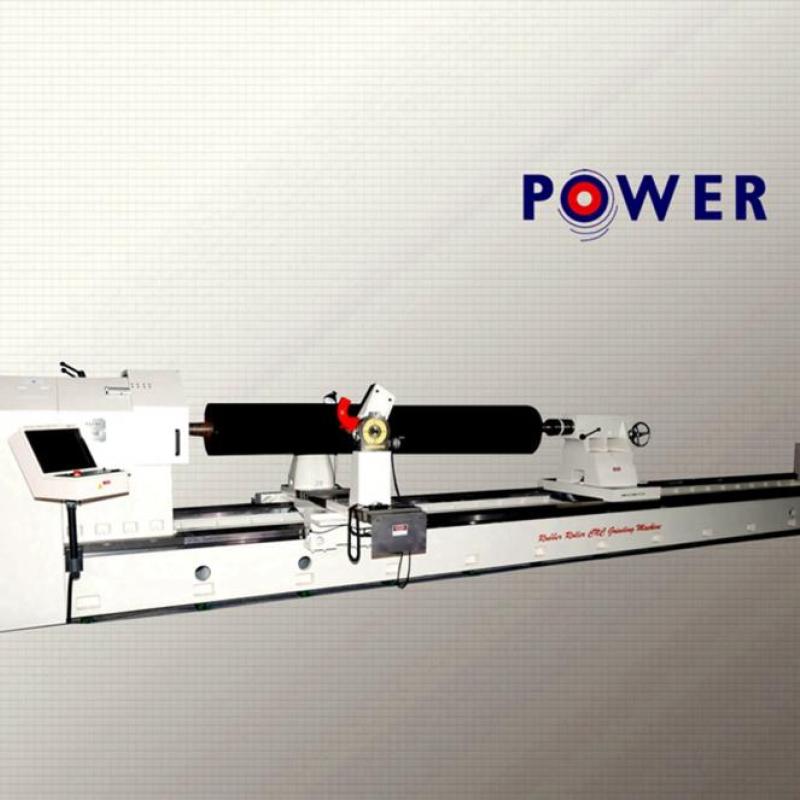

The feature of PSM series Jinan Rubber Roller CNC Roll Grinding Machine1. Standard equipment of PSM series includes: a. a full flood recirculating coolant system b. motorized tailstock c. variable speed traverse and spindle drives d. front and rear independently operated carriage tables e. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3.

Contact Now

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contact Now

Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature perfor

Contact Now

PCM-6040 Muti-Purpose Rubber Roller Stripping / Renewing / Cleaning / Recycling MachinePCM Multi-Purpose Stripping Machine is specially researched, developed and designed for treating old rubber rollers. PCM Multi-Purpose Stripping Machine has the advantages that: Old rubber can be quickly removed by a special ring cutter, a roller core would have a brand-new surface under the special belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the roller core is ensured, which replaced the traditional sand blasting process.

Contact Now

Product description1. the pcm-8040 model is appropriate for renewing commercial rubber rollers.2. eliminating antique rubber by using special ring cutter.Three. replacing the conventional sand-blasting and solvent washing technique by way of superior belt-grinding system.Four. flawlessly retaining the unique dynamic balance of the roller core.Five. giving more reliable assure for the bonding of the rubber and steel cores.6. saving expenses and labors with this stepped forward manufacturing machine.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

PSM-4020 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding gadget is specifically designed and synthetic to replace the beyond curler processing method by way of metallic production equipment. set up grinding head at the engine lathe is the beyond approach to fabricate roller, which the high-quality of roller is hard to attain the requirement of the present widespread. the primary cause lies inside the shape of lathe. in the end, it isn't the grinding gadget; the shifting spaces of the large and medium carriage desk are large than that of grinding device.

Contact Now