Because of the all-spherical of the tool function, production unit customized rubber curler groover should make nearly all of the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, at once groove, horizontal groove and exceptional formations in the appended drawing.1. factory customized rubber roller groover has our personal developed user-pleasant cnc operating system.2.

Contact Now

Because of the all-round of the device characteristic, manufacturing unit customized rubber curler groover should make nearly all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

Because of the all-round of the device characteristic, manufacturing unit customized rubber curler groover should make nearly all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

Because of the all-round of the device function, manufacturing unit custom designed rubber roller groover have to make almost all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and remarkable formations withinside the appended drawing.1.

Contact Now

PSM-1680-CNC Rubber Roller Groover / Grooving / Grinder / Grinding MachinesDue to the all-round of the system function, it can make almost all the profile of rollers.

Contact Now

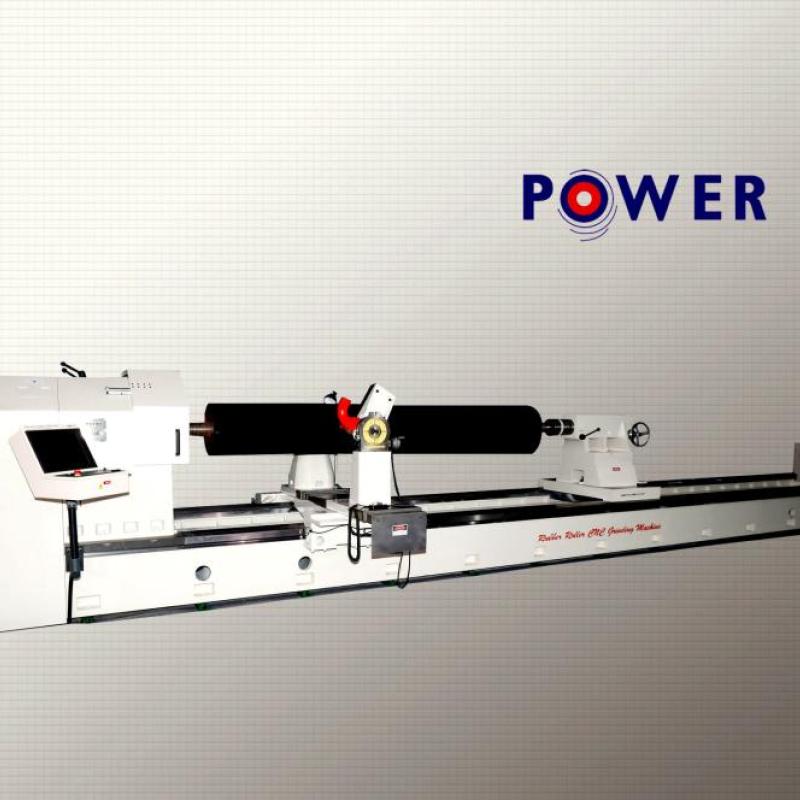

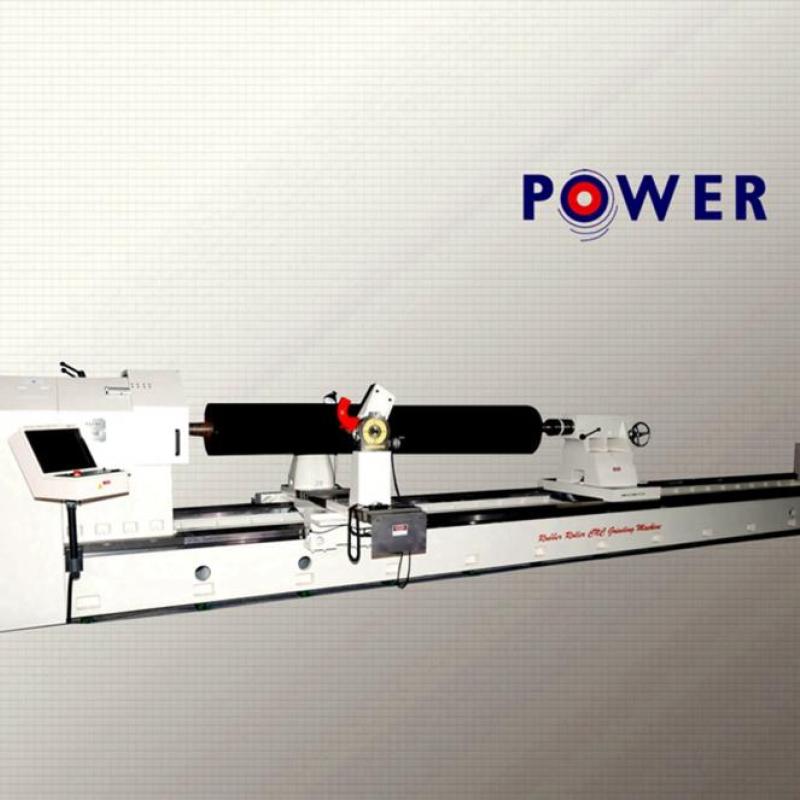

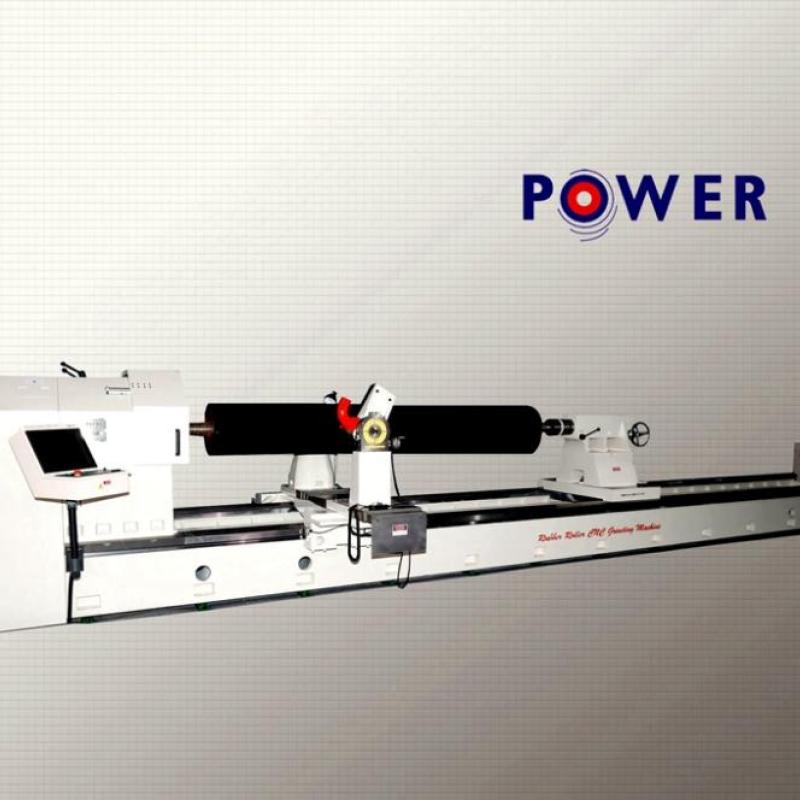

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contact Now

Because of the all-round of the device function, manufacturing unit custom designed rubber roller groover could make almost all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, immediately groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contact Now

Because of the all-spherical of the device feature, manufacturing unit custom designed rubber roller groover could make nearly all of the profile of rollers. for instance, parabolic crowning and concave, cosine crowning and concave, round, cone, coarse pitch, herringbone, diamond, without delay groove, horizontal groove and exclusive formations within the appended drawing.1.

Contact Now

The feature of PSM series Jinan Rubber Roller CNC Roll Grinding MachineDue to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1. Standard equipment of PSM series includes: a. a full flood recirculating coolant system b.

Contact Now

1. Factory custom designed rubber curler groover has our personal advanced user-pleasant CNC running gadget.2. The modern CNC gadget can without difficulty perform extra than 35 shapes at the rubber curler surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, immediately groovings, etc. 3. Remote trouble fixing characteristic availabe.4. Having all of the capabilities of our PSM collection preferred grinding machineDue to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

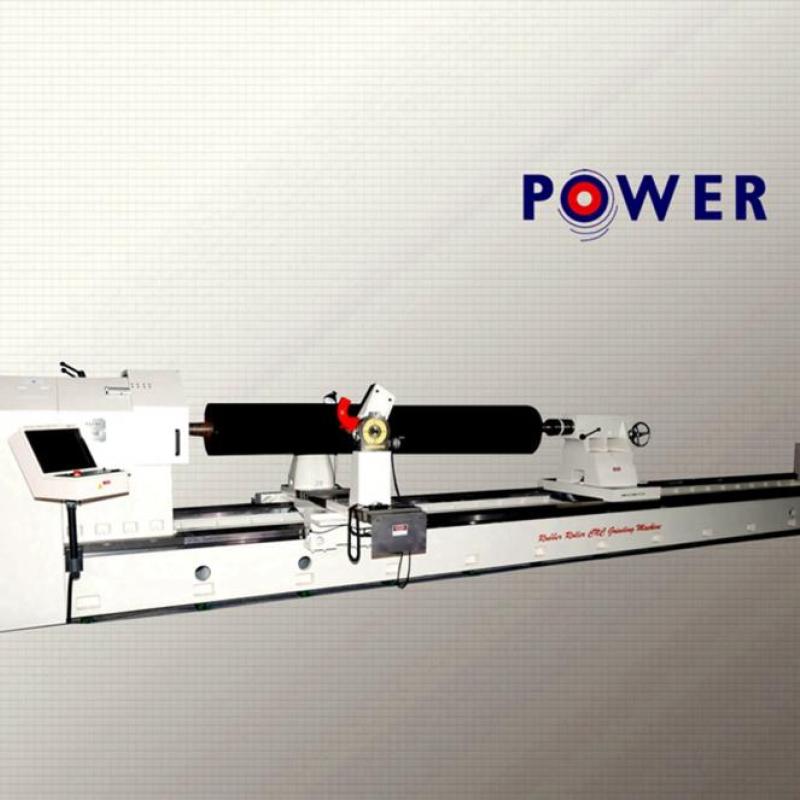

1. It has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.PSM-1680-CNC Rubber Roller Groover / Grooving / Grinder / Grinding MachinesDue to the all-round of the system function, it can make almost all the profile of rollers.

Contact Now

Because of the all-round of the device function, manufacturing unit custom designed rubber roller groover could make almost all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, immediately groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

PCM Multi-Purpose Stripping Machine is eparticularly researched, evolved and designed for treating vintage Rubber Rollers. PCM Multi-cause Stripping Machine has the benefits that: Old rubber may be quick eliminated through a unique ring cutter, a curler middle could have a brand-new floor beneathneath the unique belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the curler middle is ensured, which changed the conventional sand blasting process.

Contact Now

Due to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1.

Contact Now

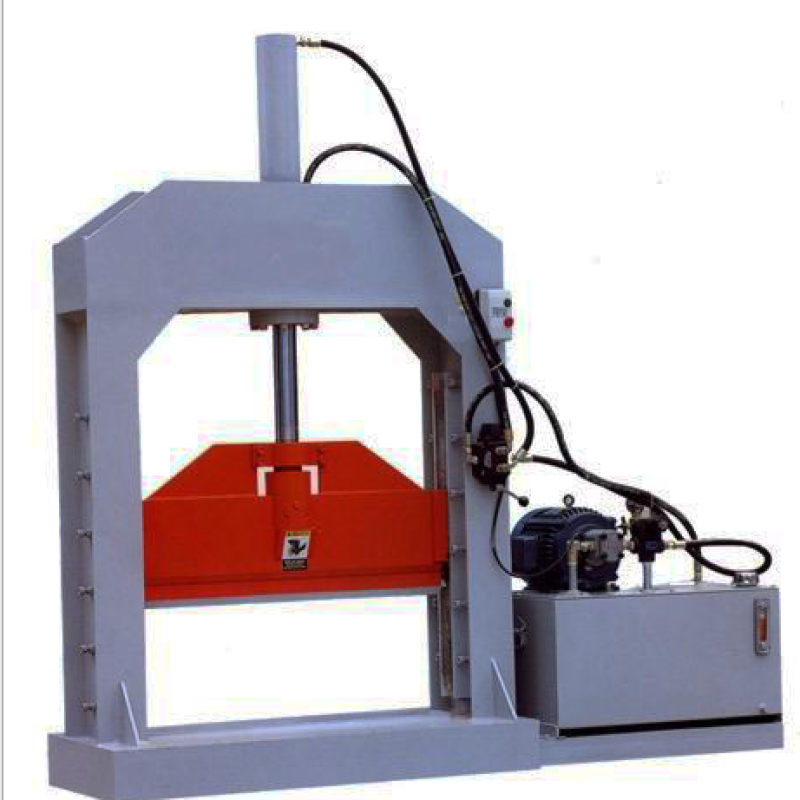

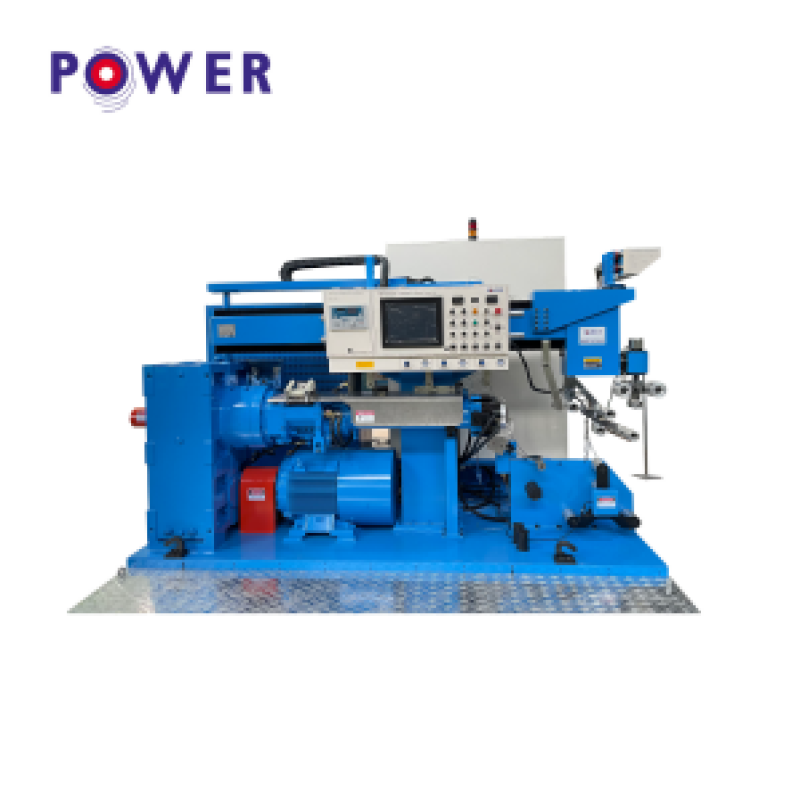

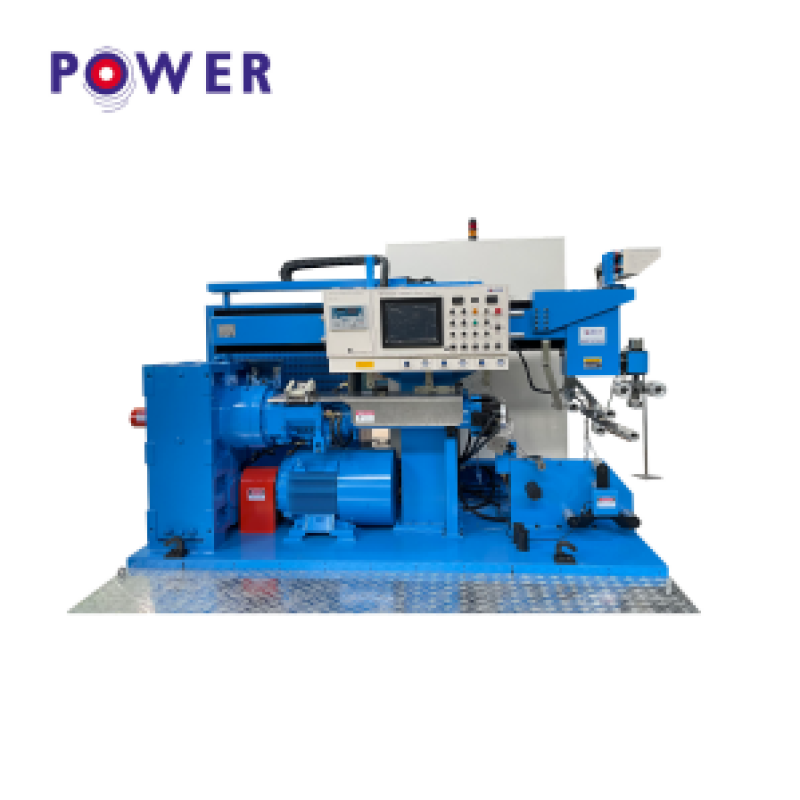

The Hydraulic rubber cutting machine The Hydraulic rubber cutting machine mainly has the cutting glue knife, the machine frame, the work oil cylinder, the base, the auxiliary work table and the hydraulic system, the electrical system and so on part composes, the cutting glue knife base is equipped with the nylon or the soft lead backing plate, protects the cutting knife the blade.Raw gum, with artificial glue in the cutting knife below, and then press the Start button, then the cutting knife in the piston rod driven by the slide along the rack down the rubber material cut.The ra

Contact Now

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

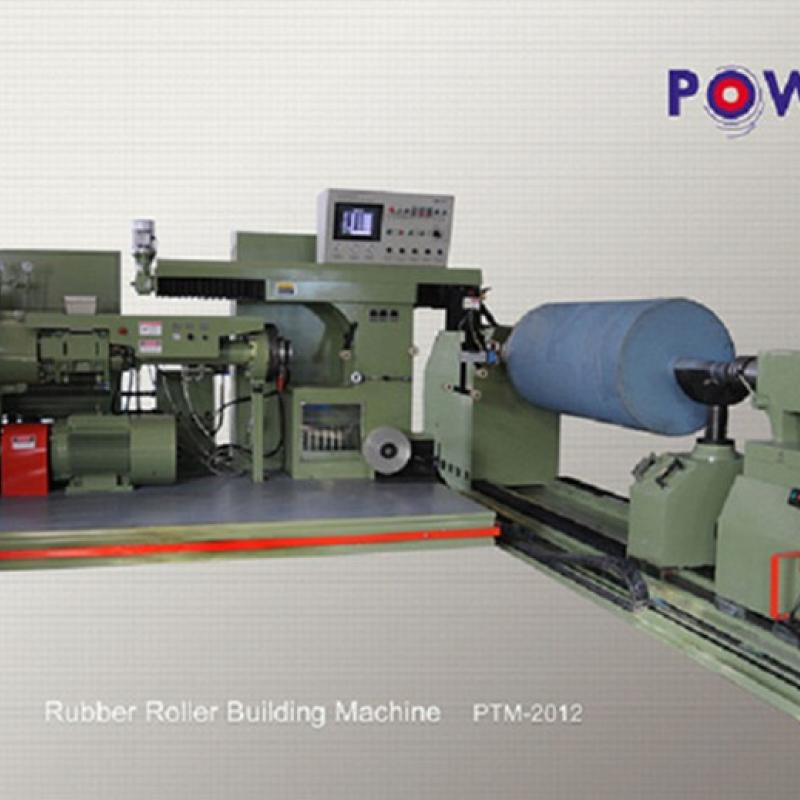

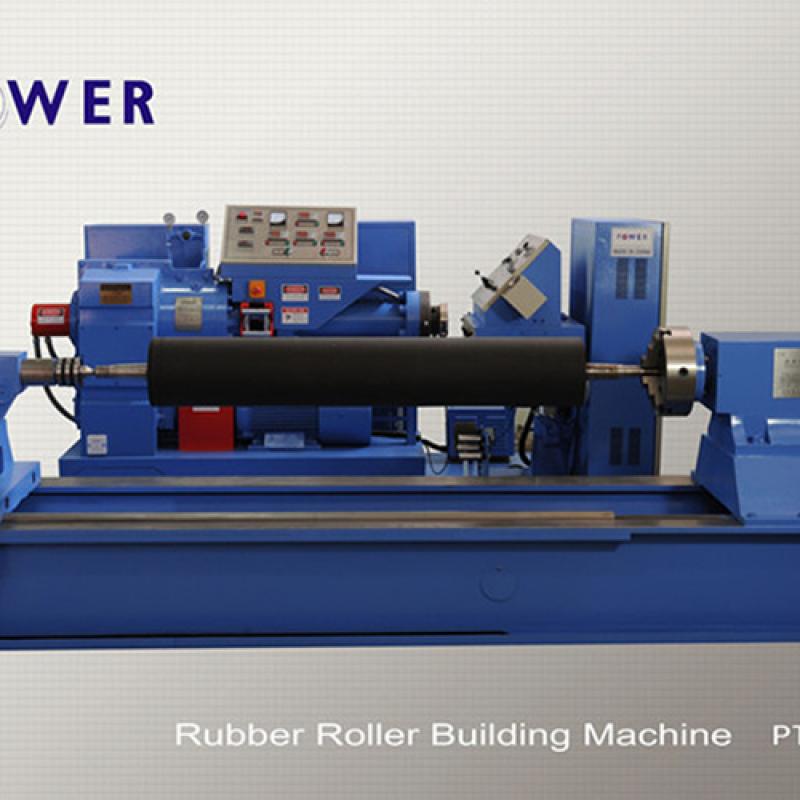

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber curler Covering Machine PTM-2012 version is appropriate for processing paper mill, mine transportation and heavy commercial rolls.2. Our rubber curler constructing system prepared with E350CS energy extruder and a whole commercial cooling system.3. The Rubber Roller Covering Machine is relevant to rubber compounding with all hardness variety 15-100A.4. The masking system is simple Installation with our expert technical support.5.

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2.

Contact Now

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

PCM-6040 Muti-Purpose Rubber Roller Stripping / Renewing / Cleaning / Recycling MachinePCM Multi-Purpose Stripping Machine is specially researched, developed and designed for treating old rubber rollers. PCM Multi-Purpose Stripping Machine has the advantages that: Old rubber can be quickly removed by a special ring cutter, a roller core would have a brand-new surface under the special belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the roller core is ensured, which replaced the traditional sand blasting process.

Contact Now

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contact Now

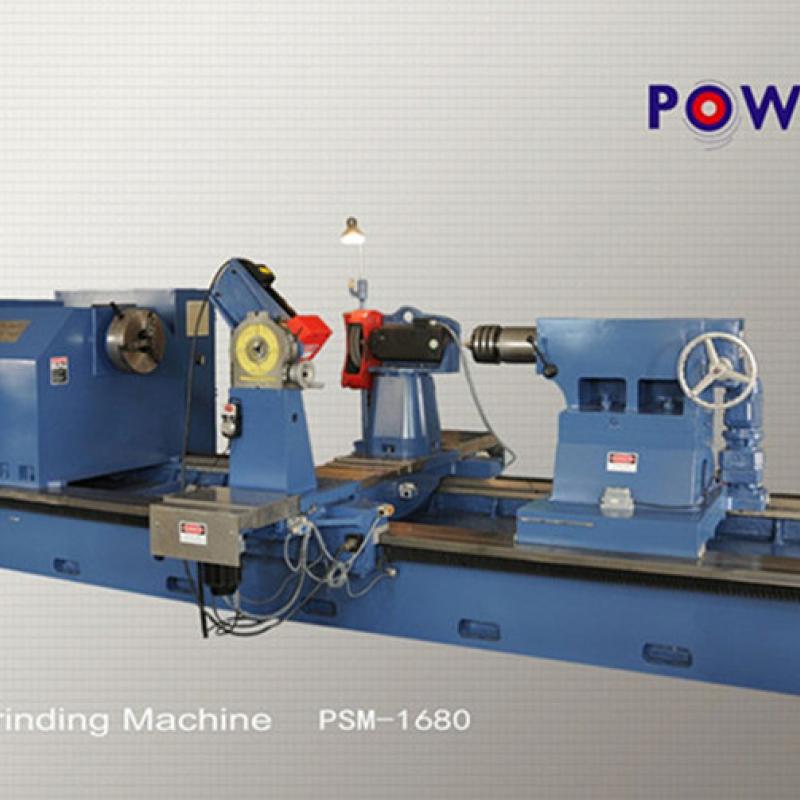

Rubber Roller Surface Grinding Machine for Paper The feature of PSM series rubber roller surface grinding machine for paper 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently operated.The feature of PSM series rubber roller surface grinding machine for paper1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contact Now

Product Description:1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.2. Machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now